Printed circuit boards or PCBs are classified into two categories – rigid and flex. Rigid PCBs are made in single, double-sided and multilayer options. PCBs are classified into three different quality classes. The classes are simply referred to as classes I, 2 and 3 where class 3 indicates the highest quality. The PCB inspection tests depend on the level of quality needed by the customer. Most electronic products have rigid double-sided or multilayer PCBs. Some products require the use of flex PCBs. All types of PCBs must undergo quality inspections. These checks ensure the PCBs can withstand the rough and tough operating conditions and environment.

Standard PCB Inspection

There are different inspection standards that apply to PCBs. Each country has its own standards but most countries agree on certain standards that are valid universally. Military PCBs have their own standards based on the applications and the types of products. Industrial standards apply to the PCBs used in industrial applications, machinery, and devices. One such standard is SJ/T10309. In addition to these standards, a device supplier may have its own standard for inspection. Some standards apply based on the design drawings, technological requirements and customer requirements.

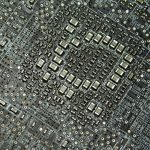

Visual PCB Inspection

Technicians trained in inspection operations use a variety of tools to perform visual PCB inspection. Depending on the requirements, they use tools like a magnifying glass, vernier caliper, ruler and other devices during this process. Visual inspection is standard and is carried out to check all types of PCBs. It is used to inspect the board’s thickness, warpage, and surface roughness. Dimensional appearance, electrical connectors, lead rail, conductive patterns, voids, burrs, open circuits, surface quality, pinholes, pit existence, scratches, and traces are some other things checked during this inspection operation.

Electrical and Technology PCB Inspection

These inspections are performed to check electrical, conductive, connectivity and insulating performances of the electrical circuit. Technological Inspection is performed to check plating and solderability adhesion. A plating plane is observed to prevent any fall-off issue.

Metalized inspection, automated optical inspection, and automated x-ray inspection are some other methods used to ensure a trouble-free and quality PCB. These checks ensure the PCB complies with the design and quality requirements. PCBs do not leave the manufacturing center until all necessary inspections and checks have been performed. The PCB fabrication company has a special department to handle quality supervision, quarantine, and inspection of PCBs. Only those PCBs that pass all such stringent tests are released and shipped to the customer.